Fiber Laser Sheet & Tube Cutting Machine

The LX 3015 FCST Fiber laser Sheet & Tube Cutter is a multi purpose heavy duty machine and its frame comes with aviation grade aliminium gantry, inovnce servo motor with vibration supression function and is a machine easy to operate.

It is used to cut Iron, aluminum, carbon steel, stainless steel, copper, hardware and another metal sheet materials.

Key Features include :

Durable Structure:8mm welded steel bed with mortise-tenon design for high rigidity, low vibration, and accurate cutting.

Efficient Cooling:External cooler improves heat dissipation, extends laser life, and stabilizes machine temperature.

Partition Dust Removal (Opt.):Stronger smoke and dust extraction for cleaner operation.

Anti-Burning (Opt.):Reduces surface temperature for safer use.

Front Electric Box (Std.):Easy control and monitoring.

Independent Electric Box (Opt.):Added safety if required.

Enhanced Ventilation:200+ air ducts boost airflow and efficiently remove smoke and heat.

Fixed High-Speed Irregular Shaped Cutting

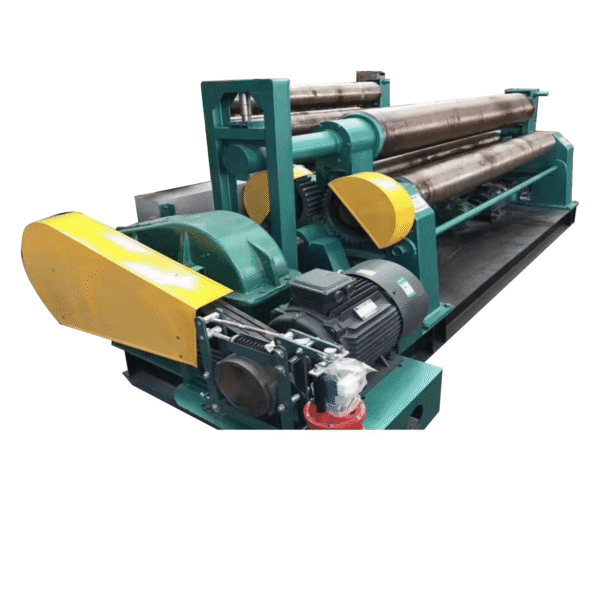

Plate / Metal Sheet Rolling Machine

Application Industries: Aerospace, shipbuilding, energy, wind tower manufacturingMaterials: Carbon steel, stainless steel, copper, aluminum, high-carbon steel

Key Features include :

Working Roller (42CrMo):

-Hollow Roller: For thin plates (≤6 mm)

-Solid Roller: For thicker plates

Hydraulic Pump:Stable, high-pressure output for smooth rolling operations.

Screw Mechanism :|Height-adjustment system using a screw-and-nut assembly for precise vertical movement.

Electrical Components:Equipped with Siemens for durability and reliable performance.

Lifting Worm Assembly:Smooth, flexible lifting for accurate positioning.

Hydraulic Motor :Easy installation and adjustment, strong performance, complete serviceability.

Reducer :Low backlash, high torque, high rigidity, low noise, high precision, long service life.

Cylinder :Provides stable pressure output, ensuring uniform bending and consistent rolling accuracy.

Engraving Machine - F9-1630

CO2 Laser Cutting (2500x1300)mm

Multi-Function CNC Cutting - F9-1313 ATC

Hydraullic Shearing Machine

Uses a moving upper blade and fixed lower blade with a set blade gap to apply linear shearing force—similar to scissors—to cut sheets of various thicknesses.

Comparison with Laser CuttingShearing machines cut only straight lines, not curves.

They offer higher efficiency with average speeds of 10–15 cuts per minute.

No programming is required, making operation simpler and faster for straight-cut production.

Key features include :MD11-1 CNC System: Simple, economical controller offering precision control; directly drives motors and supports easy accessory replacement.

Blades: Upper and lower blades with two cutting edges; made from high-quality materials for wear resistance and long life.

Guardrail: Encloses the blade area for safety.

Blade Adjustment Screw: Allows easy blade alignment and removal.

Backgauge: Controlled by MD11-1; supports and positions the sheet for stable, accurate cutting.

Pressing Cylinder: Hydraulic press mechanism that holds the sheet firmly using multiple oil cylinders and tension springs.

Hydraulic Cylinder: Main power source; the motor drives the hydraulic cylinder to generate cutting force through oil pressure.

Workbench: Supports the sheet with an auxiliary knife seat for fine blade adjustment.

Roller Table: Includes feeding rollers for smooth operation.

Electrical Box: Located on the left; all controls are placed on the front panel, with symbols indicating each function. Includes a manual oil pump for lubrication.

Foot Switch: Controls start/stop and cutting operations, improving safety and convenience.

Return Nitrogen Cylinder: Provides nitrogen to return the knife holder; nitrogen is pre-filled and recyclable.

Solenoid Pressure Valve: Regulates hydraulic oil flow and pressure to protect the system and save energy.

Application IndustriesShearing and bending machines are widely used across industries—from small non-ferrous and ferrous sheet processing, appliances, décor, kitchenware, cabinets, and elevator doors, to large-scale sectors like automotive, shipbuilding, and aerospace. CNC shearing and bending machines continue to gain importance due to their precision and efficiency.

AerospaceRequires extremely high precision; high-accuracy CNC shearing machines are used for efficient, accurate cutting.

Automobile & ShipbuildingLarge CNC hydraulic shearing machines handle major plate-cutting tasks before secondary processes such as welding and bending.

Electrical & PowerUsed to cut plates into various sizes before bending to create computer cases, electrical cabinets, refrigerator or AC housings, etc.

Decoration IndustryHigh-speed shearing machines, often paired with bending equipment, are used for metal cutting, doors and windows, and specialized décor work.

Automatic Profile Search-Edge Cutting H2-2500CC

The CNC Cutting Machine (1300×2500mm) offers precision and stability with a 3.0kW spindle and hybrid servo motor. Designed for accuracy up to ±0.015mm, it delivers fast cutting speeds of 35m/min under a robust AC380V 50Hz power system. Equipped with WEIHONG control, SCHNEIDER drive, SMG guide rail, and GXU vacuum and pressure systems, it ensures reliable and efficient industrial performance.

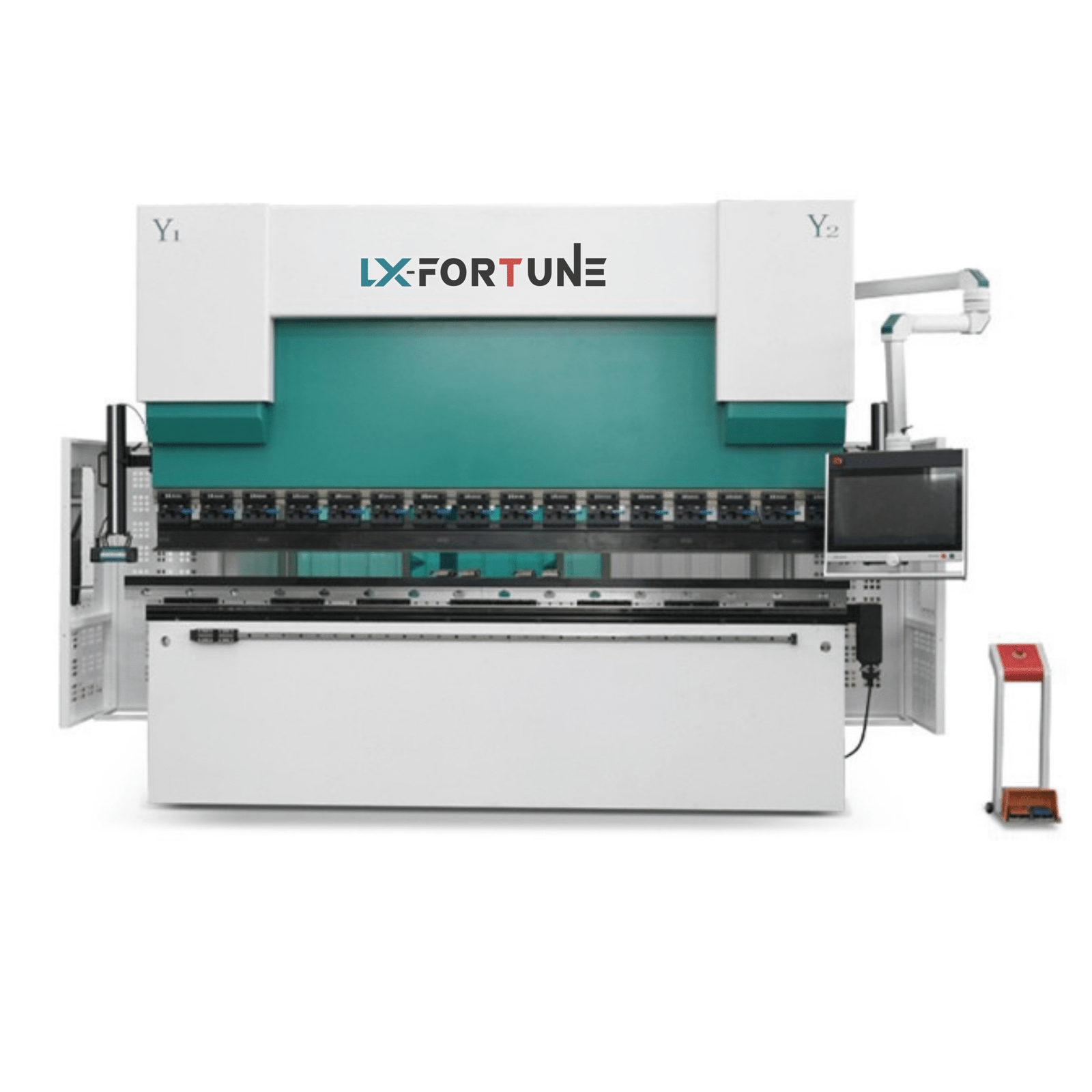

Hydraullic Sheet Bending Machine

A CNC bending machine (press brake) is a computer-controlled system used to bend and form sheet metal with high precision. It uses a hydraulic or electric press to drive a punch into a die, forcing the sheet metal between them to create accurate angles and shapes. The CNC (Computer Numerical Control) ensures programmed, repeatable, and consistent bending, ideal for complex or high-volume production.

How it works

-

Design: Parts are created in CAD software, which generates the machine’s bending instructions.

-

Setup: The operator installs the required punch and die, then inputs bending parameters into the CNC controller.

-

Bending: The sheet is positioned against the backgauge, and the CNC system moves the press to apply precise force and form the programmed angle.

-

Repeatability: Sensors and CNC adjustments ensure uniform, error-free bends across all pieces.

Key features & benefits

-

Precision: Computer control delivers high accuracy and consistency.

-

Versatility: Handles steel, aluminum, brass, and works for simple to highly complex bends.

-

Efficiency: Automation speeds production and reduces labor dependency.

-

Safety: Less manual handling enhances operator safety.